Introduction

Peeling garlic can be tedious and time-consuming, especially when processing a large quantity without crushing the cloves.

Thankfully, efficient methods and machines are available to make this process easier, such as using a garlic peeling production line.

What is a Garlic Peeling Production Line?

A garlic peeling line is an automated system designed to process large amounts of garlic quickly and efficiently.

It streamlines the peeling process by utilizing a series of specialized machines, which work together to separate, peel, and package the garlic cloves without causing damage.

How Does a Garlic Peeling Production Line Work?

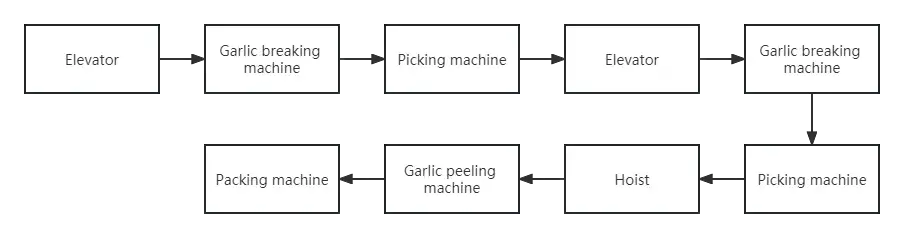

The garlic peeler line processes garlic in several stages.

First, the unpeeled garlic cloves are fed into the system, where they are lifted and conveyed through a series of machines that perform different tasks.

These tasks include separating the cloves, removing the skin, and finally, packaging the peeled garlic for distribution.

Equipment in a Garlic Peeling Production Line

A garlic peeling production line consists of several vital machines that work together to process the garlic:

Garlic Elevator:

Lifts the garlic cloves and feeds them into the production line.

Garlic Conveyor:

Transports the cloves through the different stages of processing.

Garlic Clove Separator:

Separates the individual cloves from the garlic bulb.

Garlic Peeling Machine:

Removes the skin from the garlic cloves without causing damage.

Garlic Packaging Machine:

Packages the peeled garlic cloves for distribution.

Advantages of Using a Garlic Peeling Machine

Using a garlic peeling machine offers several benefits, including:

- Faster processing time

- Increased efficiency and productivity

- Reduced manual labor

- Consistent and high-quality results

- Minimal damage to the garlic cloves

Features of a Garlic Peeler Line

Some notable features of a garlic peeling production line include:

- Customizable and scalable design to accommodate different production requirements

- Easy operation and maintenance

- High capacity and throughput

- Advanced technology to ensure gentle handling and minimal waste

Industries that Use Garlic Peeling Machines

Garlic peeling machines are primarily used in industries that require large-scale processing of garlic, such as:

- Food processing and manufacturing

- Restaurant and catering services

- Agriculture and farming

- Wholesale and retail distribution

Conclusion

In summary, a garlic peeler production line effectively peels large quantities without crushing the cloves.

By utilizing advanced technology and specialized equipment, these systems offer increased efficiency, reduced labor costs, and consistent, high-quality results.

As a result, they are widely used across various industries that demand large-scale garlic processing.