The best way to peel garlic cloves is by using a garlic peeling production line for bulk processing

Peeling garlic cloves can be time-consuming and tedious, especially when done manually.

However, using a garlic peeling production line can make the process much more efficient and hassle-free, allowing for easier bulk processing of garlic cloves.

What is a garlic peeling production line?

A Peeled Garlic Production Line is a series of interconnected machines and equipment designed to automate peeling garlic cloves.

This system not only streamlines the peeling process but also maintains the quality and integrity of the cloves.

How does a garlic peeling production line process garlic?

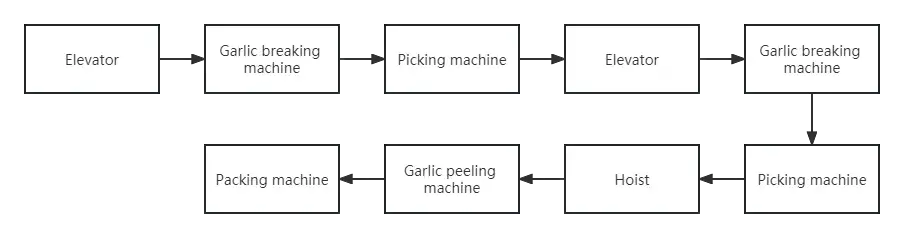

The garlic peeler production line follows a series of steps involving various machines and equipment. These steps include lifting, conveying, separating, peeling,and packaging the garlic cloves.

What equipment makes up a garlic peeling production line?

The garlic peeler line consists of several machines and equipment, including:

Garlic elevator

The garlic elevator lifts the garlic from a lower to a higher level, preparing it for further processing.

Garlic conveyor

The conveyor transports the garlic cloves from one production line stage to the next, ensuring a smooth and continuous process flow.

Garlic clove separating machine

This machine separates the individual cloves from the garlic bulbs, allowing for easier peeling.

Garlic peeler machine

The garlic peeler machine removes the outer skin from the cloves, revealing the clean and peeled cloves underneath.

Garlic packaging machine

Finally, the garlic packaging machine packages the peeled garlic cloves into bags or containers, making them ready for distribution or sale.

What are the advantages of using a garlic clove peeling machine?

Using a garlic clove peeling machine has several benefits, including:

Increased efficiency and productivity, as the device can quickly peel large quantities of garlic cloves.

Reduced labor costs and time, as the machine eliminates manual peeling.

Improved quality and consistency, as the engine ensures that the cloves are peeled evenly and without damage.

What are the features of a garlic clove peeling production line?

Some key features of a garlic clove peeling production line include:

High capacity and processing speed, allowing for large-scale production.

Minimal waste and damage to the garlic cloves.

Easy operation and maintenance, making it suitable for various industries.

In which industries is the garlic clove peeling machine primarily used?

The garlic clove peeling machine is mainly used in food processing, catering, agriculture, and pharmaceuticals, where large quantities of garlic cloves need to be peeled and processed efficiently.

Conclusion

The best method for peeling garlic cloves is undoubtedly using a garlic peeling processing line.

This advanced system offers numerous benefits, including increased efficiency, reduced labor costs, and improved quality.

By implementing this technology, businesses in various industries can streamline their garlic processing operations and stay competitive.