What is Garlic Peeling Production Line?

The garlic peeling production line is advanced processing equipment for peeling garlic cloves.

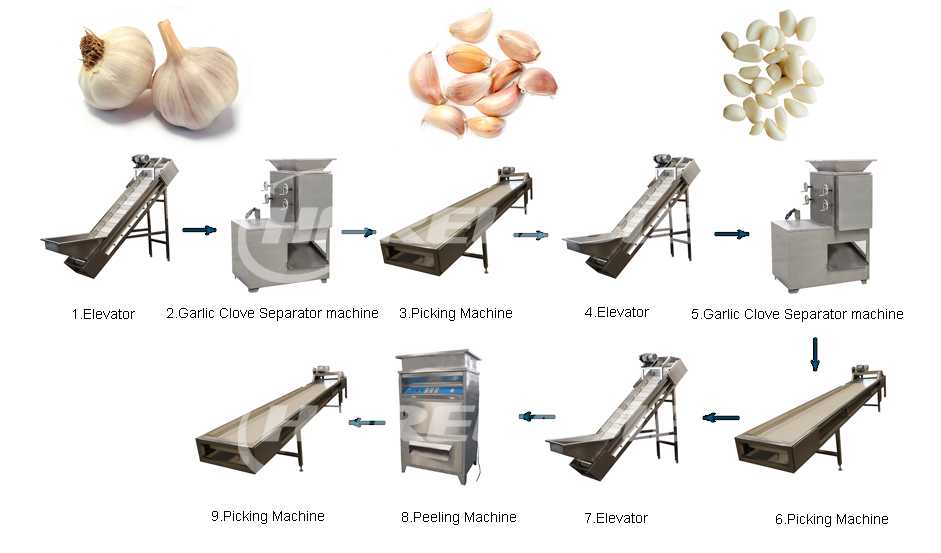

The garlic peeling production line consists of several machines, including a garlic elevator, garlic bulb separating machine, garlic picking line, garlic peeling machine, and final product picking line.

Adding other equipment, such as a garlic slicing machine and garlic air dryer, can also be used for deep processing of garlic.

The garlic peeling production line is widely used in large-scale production in food factories, canteens, and individual businesses.

Advantages of Garlic Peeling Production Line

The garlic peeling production line complies with national hygienic standards, ensuring the safety and health of the food it processes.

It operates quickly, reducing labor costs and making it easy to use.

Additionally, it does not damage the garlic and produces a high yield of garlic cloves.

The procedure of the Garlic Peeling Production Line

The process flow of the garlic processing production line includes elevating garlic, separating garlic bulbs, picking, elevating again, peeling garlic, and then picking the finished product.

Market Prospect for Garlic Peeling Production Line

Garlic is a highly versatile food used in various industries, including food, health food, and pharmaceuticals.

It is abundant in functional ingredients that offer many health benefits, such as digestion assistance, immunity enhancement, virus control, and liver protection.

Therefore, the demand for garlic continually increases, and the garlic peeling production line has enormous market potential, making it a wise investment choice.

Attention

Always switch off the power source first and clean it with a dry cloth when cleaning the machine.

Do not clean the main engine of the machine with water.

If not using the machine for an extended period, store it in a dry, ventilated place to keep it clean and dry.

Conclusion

In conclusion, the garlic peeling production line is a reliable and efficient processing equipment for large-scale garlic production.

Investing in this equipment would be an excellent decision with the increasing demand for garlic in various industries.

It complies with hygienic standards and is easy to operate, reduces labor costs, and produces high yields of well-peeled garlic cloves.

However, taking necessary precautions during cleaning and storing the machine is essential to ensure its longevity and durability.

The garlic peeling production line is necessary for any garlic processing industry seeking higher efficiency, productivity, and profitability.