In the modern food industry, potato chips production lines have become

indispensable for manufacturers looking to meet the growing demand for

high-quality, crispy snacks.

This article explores the benefits, features, and core differences between small-scale potato chips production lines and full-automatic potato chips production lines, helping you make an informed choice for your business needs.

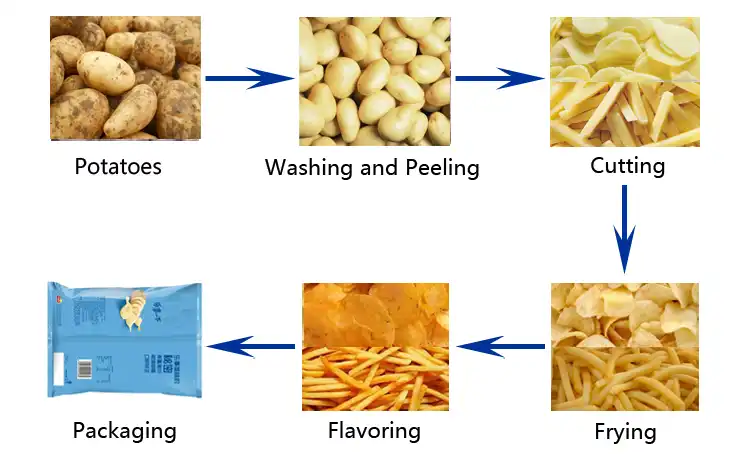

The potato chips production line process includes washing, peeling, slicing,

frying, seasoning, and packaging. With advanced automation technology, these

lines streamline production, reduce labor requirements, and ensure consistent

quality, making them ideal for both small-scale and large-scale

manufacturing.

Potato Chip Production Line Process Flow:

Capacity: 50kg/h, 100kg/h, 150kg/h, 200kg/h, 300kg/h, 400kg/h, 500g/h

1. Small-Scale Potato Chips Production Line

A small-scale potato chips production line is a compact and cost-effective

solution for businesses that are just starting or operating on a smaller budget.

This type of production line is ideal for boutique snack companies, small food

factories, or entrepreneurs looking to enter the snack industry.

Features of Small-Scale Potato Chips Production Line

Compact Design: Small-scale production lines take up minimal space, making them suitable for smaller facilities.

Lower Investment Cost: These lines are budget-friendly while still delivering quality results.

Ease of Operation: Designed with simplicity in mind, these lines are user-friendly and require minimal training.

Customizable Output: Adjustable settings allow you to produce potato chips in various thicknesses and styles.

Energy Efficiency: Optimized for lower energy consumption, helping you reduce operating costs.

2. Full-Automatic Potato Chips Production Line

A full-automatic potato chips production line is a highly advanced and fully

integrated system designed for large-scale production. With state-of-the-art

automation, these lines ensure efficient, high-volume output with minimal human

intervention.

Features of Full-Automatic Potato Chips Production Line

High Capacity: Capable of processing large quantities of potatoes, meeting industrial-scale demands.

Advanced Automation: Fully automated from start to finish, reducing the need for manual labor.

Consistent Quality: Ensures uniform slicing, frying, and seasoning for premium-quality chips.

Customizable Configurations: Offers flexibility to produce a wide variety of chip styles, including plain, ridged, and flavored options.

Hygienic Design: Made with food-grade materials and adhering to strict sanitation standards.

Energy and Cost Efficiency: Optimized for reduced energy consumption and lower operational costs.

Why Choose Our Potato Chips Production Lines?

Industry Expertise

With years of experience in food processing machinery, we understand the

unique needs of our clients. Our production lines are designed to meet both

small-scale and industrial requirements.

Customization Solutions

Whether you need a small-scale potato chips production line or a full-automatic potato chips production line, we offer tailored solutions to fit your specific business goals.

Advanced Technology

Our machines incorporate the latest automation technologies, ensuring

efficiency, quality, and reliability.

Comprehensive Support

From installation to maintenance, our expert team provides end-to-end support, ensuring seamless operation.

Competitive Pricing

We offer high-quality equipment at competitive prices, delivering excellent value for your investment.