Introduction

Garlic is a common ingredient in many dishes, but peeling it can be time-consuming and messy.

Luckily, there is a solution that allows you to peel garlic without touching it: using an automated garlic peeling production line.

The Process of Automated Garlic Peeling

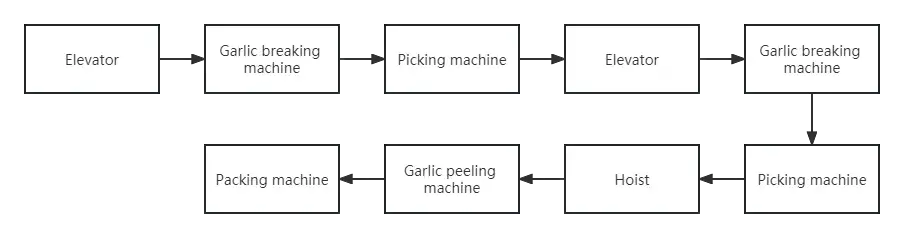

The process of peeling garlic with an automated production line is straightforward:

1.The garlic heads are loaded onto the production line using advanced machinery and automation technology.

2.The garlic heads are peeled using a combination of air compression, vibration, and water pressure. After peeling, the garlic heads are sorted and separated based on their quality and size.

3.The peeled garlic heads are unloaded automatically, ready for further processing or packaging.

Equipment Used in Automated Garlic Peeling

The primary equipment used in automated garlic peeling production lines includes:

Loading Systems

Loading systems transport garlic heads from the storage area to the production line.

They come in various sizes and configurations, depending on the production volume and the type of garlic being processed.

Peeling Machines

Peeling machines use a combination of air compression, vibration, and water pressure to peel garlic heads quickly and efficiently.

They can handle large volumes of garlic and come in different sizes and configurations, depending on the production needs.

Sorting Machines

Sorting machines separate peeled garlic heads based on their quality and size.

They can automatically remove damaged or defective garlic heads, ensuring that only high-quality garlic is sent for further processing.

Unloading Systems

Unloading systems transport peeled garlic heads from the production line to the following processing or packaging stage.

They can be customized to fit the specific needs of the production facility.

Uses of Peeled Garlic

Peeled garlic is versatile in many dishes, including marinades, sauces, dressings, and soups.

It adds a distinct flavor and aroma to any recipe, making it a staple in many cuisines worldwide.

Cultural Significance of Peeled Garlic

In different parts of the world, people use peeled garlic in various ways. In some cultures, peeled garlic is ground into a paste and used as a base for many dishes.

It is sautéed or roasted in others to bring out its natural sweetness and aroma.

Some even eat raw peeled garlic as a natural remedy for various health issues.

Conclusion

In conclusion, automated garlic peeling production lines are the most efficient and hygienic way to peel garlic without touching it.

They offer a quick, efficient, cost-effective solution for large-scale garlic processing operations.

Peeled garlic is a valuable ingredient in any kitchen or food production facility, with its many uses and cultural significance.