The banana chips production line realizes automatic production, large output, saves a lot of labor, frying and dehydrating the food at low temperature, which can effectively reduce the damage of high temperature on the nutritional composition of food.

The process of production line is simple and safe. Energy saving. High return on investment.

Capacity:100kg/h,150kg/h,260kg/h,400kg/h,500kg/h

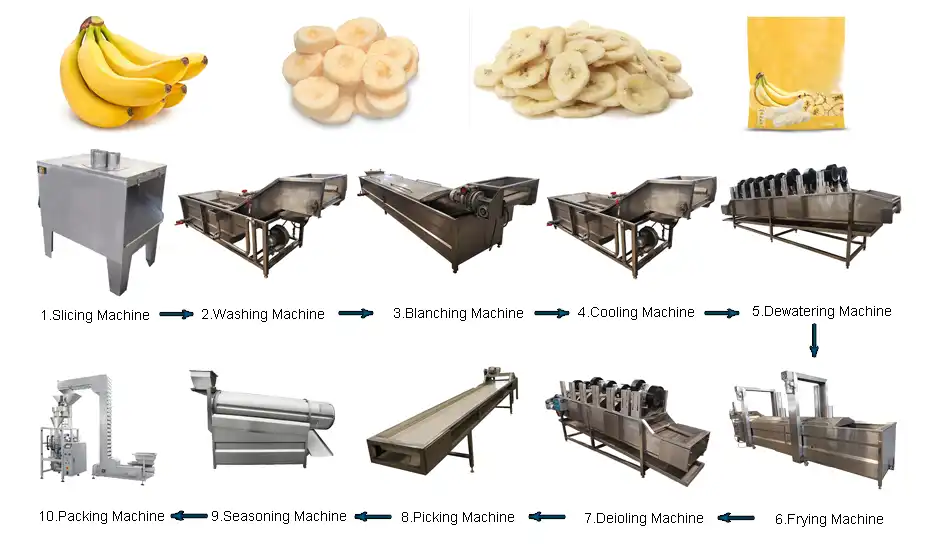

Full Automatic Banana Chips Line Processing Flowchart:

Full Automatic Banana Chips Line Process points:

1. Banana chips cutting machine: The peeled bananas are then sliced into even thickness using a machine slicer.

2. Banana chips blanching machine: The banana slices are then blanched in hot water for a few minutes to remove any impurities and to soften them.

3.Banana chips dewatering machine: The dehydrating machine is used to remove the excess moisture from the blanched material, which makes it easier to fry.

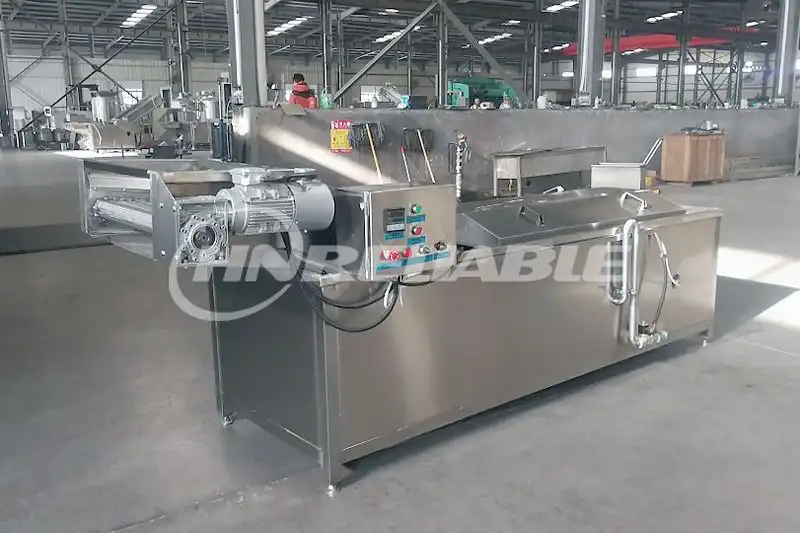

4. Banana chips frying machine: The blanched banana slices are then fried in hot oil until they turn crispy and golden brown.

5. Banana chips deoiling machine: The deoiling machine is used to remove the excess oil from the fried material, which makes it healthier and less greasy.

6. Banana chips seasoning machine: The fried banana chips are then seasoned with salt or any other desired seasoning.

7. Banana chips packaging machine: The cooled banana chips are then packed in air-tight bags or containers using an automatic packaging machine.