Introduction of Dehydrated Garlic Slice Production Line

Dehydrated garlic flakes can be consumed directly or as a food supplement and recovered by soaking in warm water, with a long shelf life, and are easy to use.

The dehydrated garlic slices production line is an automatic production line that can produce dehydrated garlic slices in large quantities.

Capacity: 300kg/h,600kg/h,1200kg/h, and 2000kg/h

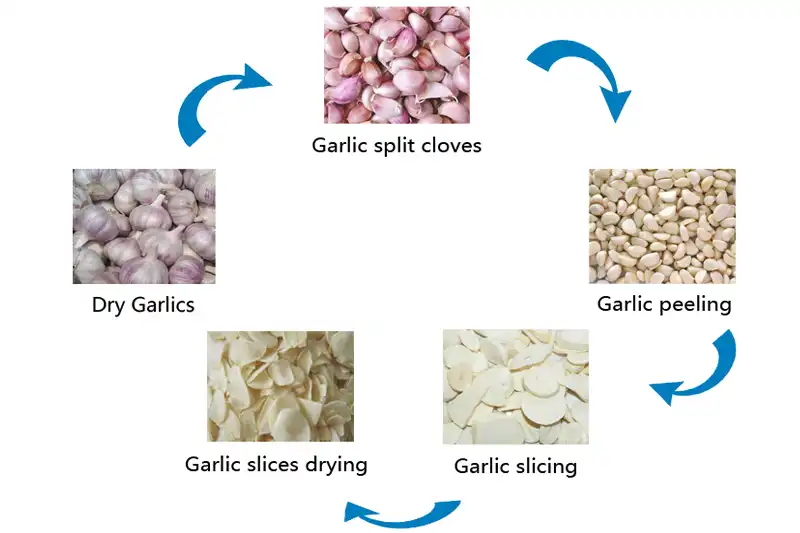

Processing flow of Dehydrated Garlic Production Line

Main Products of Dehydrated Garlic Slice Line

Elevator

Elevator is a common equipment in garlic processing line, which is used for lifting and conveying garlic in different equipment pieces, usually need to match different quantity according to the output.

Garlic splitting machine

The garlic splitter uses soft rubber wheels that meet environmental standards to perform a hand-peeling simulation to peel the garlic bulbs. The clearance of the casters of the garlic splitter can be adjusted, and the garlic balls can be used in any size.

The garlic head that has been roughly split has the advantage of no damage to the garlic cloves and a high peeling rate.

The garlic splitting machine is easy to operate with a built-in fan; garlic skin, garlic rod, and garlic clove are separated automatically, and one person can use them alone.

Picking conveyor

After coarse separation, the garlic cloves are transported to the following process through the garlic picking conveyor while picking the residual or incomplete cloves, which is convenient, time-saving, and continuous.

Garlic Peeling Machine

The garlic peeling machine adopts the pneumatic principle to process the broken cloves into garlic rice without any damage, the cloves can be peeled cleanly without soaking, and the peeling rate can reach more than 95% when the garlic is dry. The garlic peel and rice are separated automatically.

Garlic Slicing Machine

The garlic slicing machine adopts the working principle of the rotary knife to cut the garlic cloves into garlic slices of standard size.

Garlic Washing Machine

Garlic washing machine adopts the principle of bubble washing, which can wash off the impurities on the surface of garlic and the waste materials and trimmings produced in the cutting process.

Garlic air drying machine

The garlic air drying machine can automatically turn over with the conveyor belt during the conveying process.

Then with the powerful fan located above the conveyor belt, the cleaned garlic slices can be blown dry for subsequent processing.

Garlic drying machine

Although the cut garlic slices remove the water on the surface, there is still a certain amount of water content inside the pieces.

After the drying treatment of the garlic drying machine, the water content in the slices is kept within a reasonable range, which helps to preserve the cuts for a long time.

Garlic Air Cooling machine

The primary function of the garlic air cooling machine is to cool down the garlic slices after drying by the fan, which is convenient for later packing, transportation, and storage.

Packing Machine

The packaging machine used in the production line of dehydrated garlic slices needs to be customized according to the package's weight, quantity, and size.